Objectives

The main objective of this proposal is to develop a new ceramic reinforced hot work tool steel based on the actual DIN 1.2343 steel with the aim of increasing a 30% die’s life. It will be performed overcoming the actual failure mechanisms that take place at high temperatures during HPDC operations.

Technical objectives

The technological solution will be a new steel grade. This can be broken down into the following technical objectives:

- To define and quantify the mechanical, thermal and metallurgical requirements of the steel to be developed for HPDC.

- To design the chemical composition of the new steel based on the current DIN 1.2343 and the reinforcing carbides and alloying element percentages (which provides stable phases and suitable thermal and mechanical properties after machining, quenching and tempering treatments) to undergo in an effective manner the failure modes inherent to high pressure die casting process.

- To define a heat treatment cycle (quenching and tempering) adjusted for the optimal alloy system in order to meet the in-service condition requirements.

- To evaluate the thermal fatigue response of actual and developed alloys by testing at temperatures between 250-625ºC for 100.000 cycles.

- To evaluate and to predict the response of the developed steel to 3D forging by process simulation with a Gleeble technique and to define the forming maps for the most suitable steel to be produced at industrial scale.

- To evaluate the internal stresses by non-destructive methods in the different steps of die making (ESR casting and refining, 3D forging, machining, heat treatments).

- To validate the die manufacturing parameters of the new steel for the standard fabrication procedures (Machining, finishing, EDM, welding). To analyze the potential of the new steel in terms of cost (LCC), environmental impact (LCA) and performance.

- To validate and quantify the industrial improvements of the proposed new hot work tool steel at the industrial scale by a final user.

Environmental objectives

The aim is to increase the sustainability of the process industry i.e. reduction of energy/raw materials consumption, greenhouse gas emissions and as well as allowing the spread up of the use of light cast metals in the automotive sector, with a reduction in emissions and fuel consumptions.

Social objectives

- To strengthen the competitiveness of the European steel, die making, foundries and transportation industry, resulting in job retention, exportable high-value products for the industry and the corresponding jobs, and wellbeing in Europe.

Use Cases

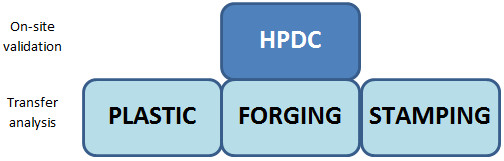

The HPDCSTEEL developments will be demonstrated in one use case:

- Aluminium High Pressure Die Casting (HPDC: The new steel grade will be developed at SWG in order to increase the life of the die, increasing part quality and decreasing associated costs. Detailed laboratory and industrial test will be implemented for the development of the steel and to improve factors such as hardness, mechanical properties and impurities. The manufacturing of reinforced steels will be developed at Lebario Romania and the prototype die will be installed in the Santena 2A SPA plant.