Work Packages

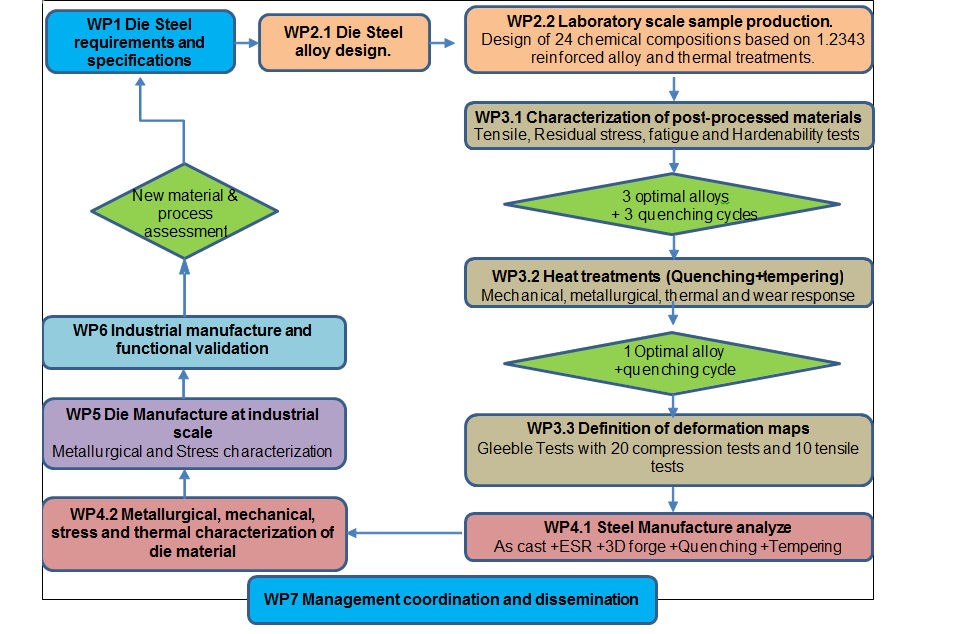

The work programme is broken down into 7 WPs, as described below:

WP1. Die steel requirements and process specification (Leader: 2A SPA). Month 1 – Month 6

This WP is concerned with the identification of the mechanical, thermal and metallurgical properties requirements for the in life service of the hot work HPDC steel.

WP2. Die steel alloy design and laboratory scale samples production (Leader: TECNALIA). Month 4- Month 18

Failure modes and properties identified in WP1 will be key parameters to design a new steel grade. Using DOE, 24 alloys with different percentages of carbides and minor and mayor alloying elements will be produced in laboratory scale.

WP3. Material characterization (Leader: SWG). Month 10 – Month 21

- To characterize the 24 alloys obtained from WP2 by hardness, resilience, thermal fatigue and tensile test and by microstructural characterization.

- To preselect 3 alloy systems through hardenability, resilience, thermal fatigue, residual stress and tensile test (for evaluation of optimal properties) from initial 24 alloys.

- To design and apply quenching and tempering cycles for the 3 preselected alloys and characterising their properties, selecting an optimal alloy.

- To analyse the behaviour of the optimal alloy in terms of machinability, welding and finishing.

- To define the deformation maps and ductility dwells with a Gleeble for the optimal alloy characterisation.

- To get a complete metallurgical and mechanical characterisation of the optimal new material to be used in WP4 for Steel manufacturing analyse, WP5 Die manufacturing Analyse and WP6 Industrial Validation.

WP4. HPDC new steels manufacture at industrial scale (Leaser: SWG). Month 16- Month 27

- To produce the master alloys for the industrial casting of the new tool steel

- To produce bars of the new tool steel to characterise the new steel produced at industrial level and to determinate the influence and working parameters and process to obtain the best properties.

WP5. Die manufacture at industrial scale (Leader: LEBARIO RO). Month 19 – Month 33

The main objectives of this work package are:

- To manufacture HPDC dies for their use in 2A SPA casting industrial test with the new steel

- To determinate the machining parameters, limitations and costs of the new steel

- To determinate the finishing operation parameters, limitations and costs of the new steel

WP6. HPDC industrial validation (Leader: 2A SPA). Month 30 – Month 42

- To perform HPDC tests with new HPDC dies under industrial conditions

- To study the response of new steel and make the comparison with the current one

- Characterization of the in service properties of the new steel

- Estimation of the overall economic impact (LCC) and environmental (LCA) of the manufacturing and use of the new steel

- Analysis of the potential use of the new steel for other casting processes dies or tooling.

- To define exploitation plan of results obtained during project development.

WP7. Management, coordination and dissemination (Leader: TECNALIA). Month 1 – Month 42

- To coordinate the partners in order to ensure that the project objectives are met and the planning is maintained.

- To provide adequate means of dissemination of the results. Workshops or dissemination events will be organized. Participation in conferences is also considered.

- To follow-up other research programs aiming at a similar topic, looking for synergies and exchange of information between them.

- To manage IPR (Intellectual Property Rights) related to acquired knowledge and results